Applicable materials: metal magnesium, aluminum slag, limonite, river sand, fly ash, calcite, iron slag, silver powder, iron ore, etc.

The ceramic ball mill has high crushing efficiency and wide application range. It can play a good role in a variety of medium crushing, fine crushing and superfine crushing operations.

Feeding size

<25mmPower

2.2-75kw

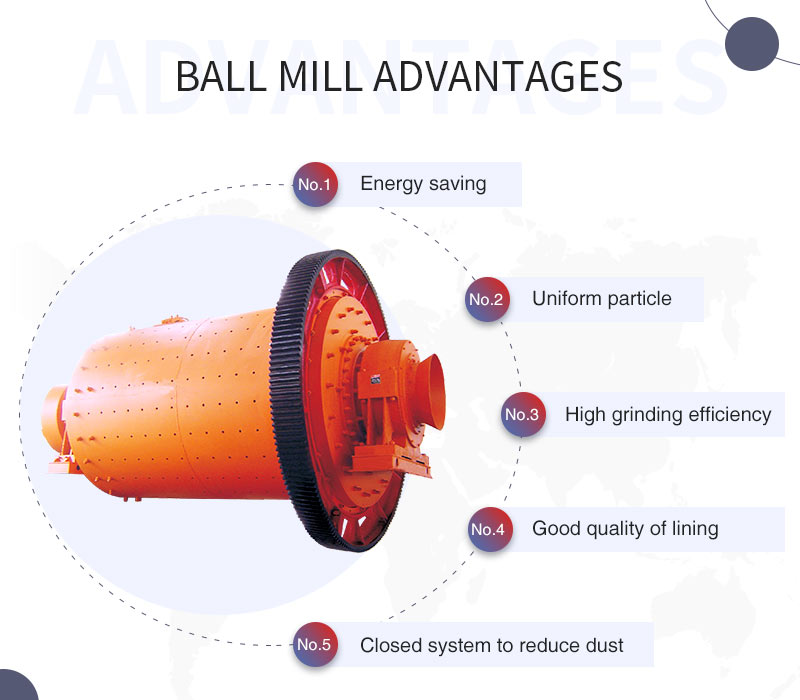

Ceramic ball mill is mainly used for mixing and grinding materials, uniformity of product fineness and power saving. It can be a dry or wet mill. The machine can be used according to the production needs of different types of liners to meet different needs. The fineness of the grinding operation depends on the grinding time. Suitable for mixing and grinding of common and special materials. Users can choose the appropriate model and liner and media type based on the specific gravity, hardness, and production factors.

The material enters the mill through a hollow shaft screw barrel from a drum feeder. The grinding machine body is provided with a grinding medium. When the cylinder body rotates, the grinding medium is attached to the inner wall lining surface of the grinding machine cylinder due to the inertia centrifugal force, and is rotated to be brought to a certain height together with the cylinder body, by means of The gravity acts freely to drop and crush the material in the cylinder.

In addition to the cyclic movement of ascending and falling, the grinding medium also causes sliding and rolling in the rotating cylinder body, causing grinding action between the grinding medium, the lining plate and the material to grind the material.

Our customers come from all over the world. If you are interested in our products, you can contact us immediately! Or send an email at info@hxjq.com

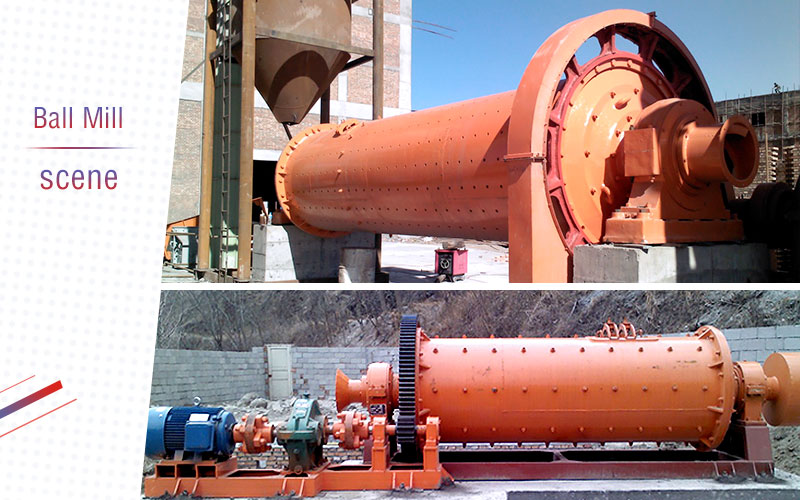

Processing Capacity: 3000T/D

Processing Material: Gold ore

Henan Hongxing Mining Machinery Co., Ltd. (HXJQ) covers an area of 350,000 square meters which includes 260,000 square meters of heavy duty industrial workshops.

Please tell us your needs like expected capacity, we have professional engineers to customize the proper production process for you.