Applicable materials: artificial stone sand such as iron ore, quartz stone, gold ore, copper ore, limestone, construction waste, cement clinker, various ores or rocks.

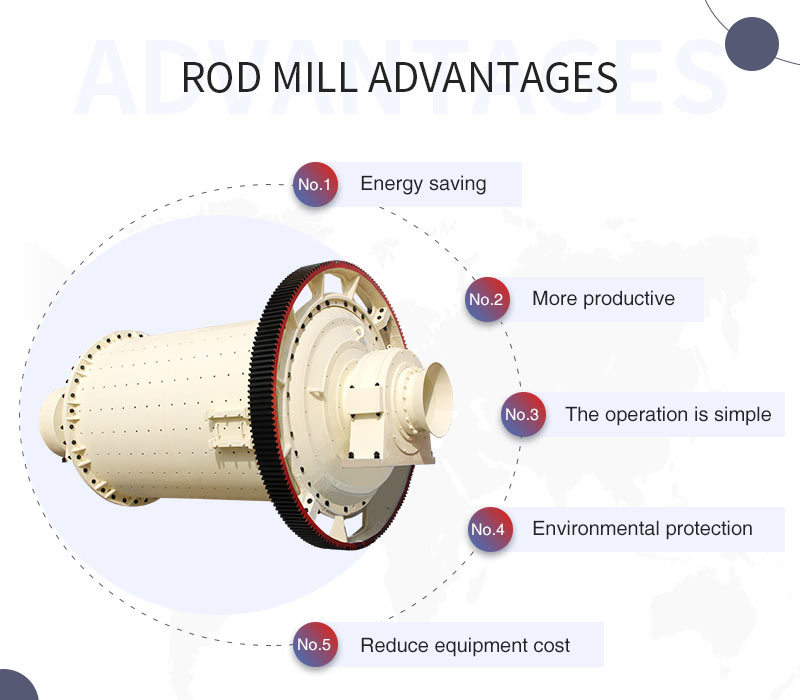

The company adopts advanced controllable feeding and discharging technology, and the actual grinding material should be matched with the suitable grinding body to change the traditional surface contact to line contact so that the discharge granularity is more uniform, the output is higher.

Production capacity

0.62-180t/hFeeding size

≤25-≤50mm

The Hongxing Rod Mill manufacturer adopts advanced controllable feeding and discharging technology, combined with the actual grinding material, with the appropriate grinding body, and the traditional surface contact is changed into line contact so that the discharge granularity is more uniform and the output is higher. Rod mills are widely used in refractory, chemical, metallurgical, glass and other industries and for grinding operations with relatively high uniformity of finished products.

The motor is driven by the reducer and the peripheral large gear reduction drive or by the low-speed synchronous motor directly through the peripheral large gear reduction drive to drive the cylinder to rotate. The cylinder is filled with a suitable grinding medium - steel rod. Under the action of centrifugal force and friction force, the grinding medium is lifted to a certain height and falls in a falling or falling state. The material to be ground continuously enters the inside of the cylinder from the feeding port and is moved by the grinding medium. Smash, and discharge the product out of the machine through the overflow and continuous feeding force to carry out the next process.

Our customers come from all over the world. If you are interested in our products, you can contact us immediately! Or send an email at info@hxjq.com

Processing Capacity: 3000T/D

Processing Material: Gold ore

Henan Hongxing Mining Machinery Co., Ltd. (HXJQ) covers an area of 350,000 square meters which includes 260,000 square meters of heavy duty industrial workshops.

Please tell us your needs like expected capacity, we have professional engineers to customize the proper production process for you.