Our industries are changing and advancing quickly,

and we know you need to be responsive to those changes.

Our industries are changing and advancing quickly,

and we know you need to be responsive to those changes.

04

Jun 2019

Aileen

In recent years, with the rapid development of the mineral processing industry, in the market, there is an increasing demand for mineral processing equipment, especially ball mills. However, do you really know about ball mills? Next, the introduction of a ball mill will be for you by our experts.

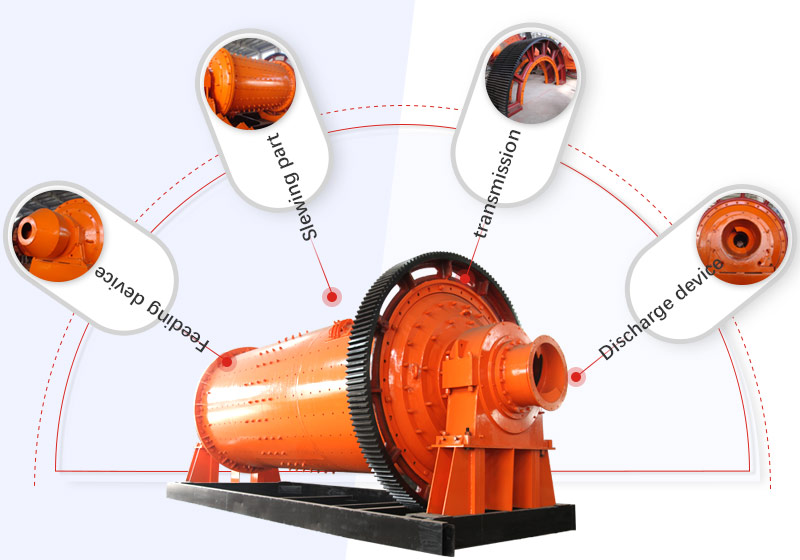

Although there are different types of ball mills due to the differences in manufacturing method, specification, discharging method, they generally have the same structure, which mainly consists of the feeding devices, support devices, rotary parts, transmission devices, and discharging devices.

In a word, the structure of a ball mill is simple. While the tube is rotating, with the effect of friction force and centrifugal force, the grinding media are lifted to a certain height and they will fall down with gravity to hit and grind the material inside the tube. As soon as the ground material can meet the requirement in particle size it will be discharged from the outlet.

As the main equipment used to produce mineral particles, a ball mill can effectively separate minerals from gangue. Then, what are the advantages and disadvantages of it?

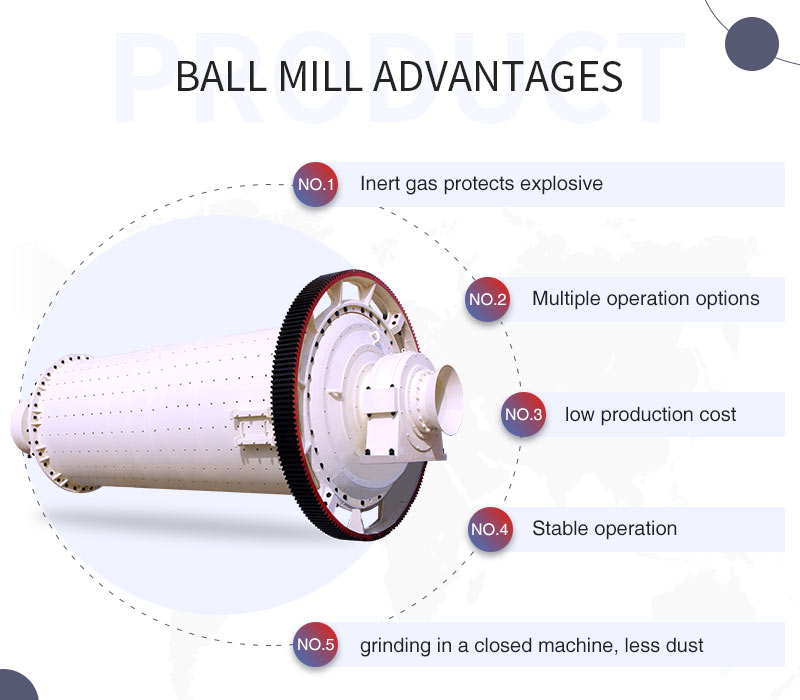

Advantages: Ball mills can be applied to process a variety of ores. Besides, it is of good grinding effect, even particle size of the final product, high handling amount, safe and stable operation, and high efficiency. It can be in the operation for a long time in succession. It has two grinding methods, the dry-type grinding method and the wet-type one, which can be chosen from by users according to their actual situation. It is of good sealing property, which can decrease pollution and save resources.

Disadvantages: A ball mill belongs to big-scale equipment so the investment cost of its production is quite high. The volume of its tube is big and the electric motor used to drive the rotary body costs energy. Besides, the machine must be worn to some extent by hard materials, which needs some cost for maintenance.

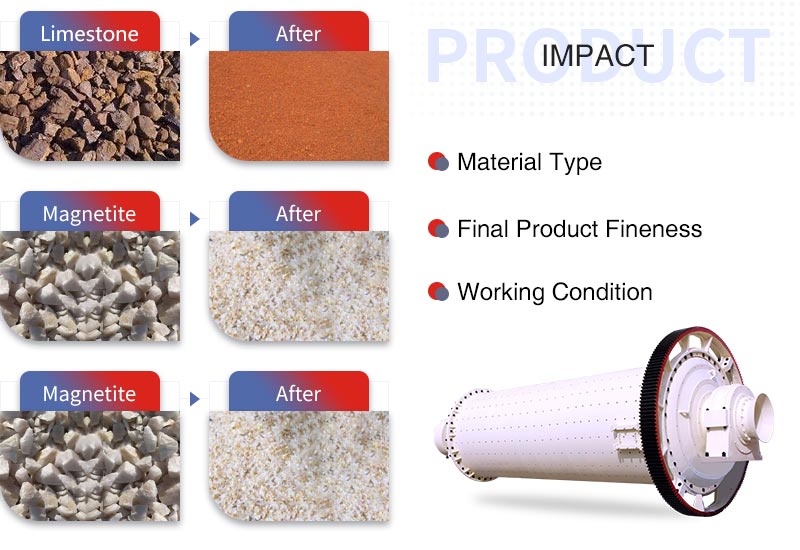

1. Material Type

Materials are different in hardness, humidity. Lower the hardness of the material is, higher the productivity of a ball mill is. On the contrary, if the material is of high hardness, the ball mill’s productivity will be relatively low.

2. Final Product Fineness

Smaller the required particle size of the final product is, the longer time it will take a ball mill to grind the material, which will decrease the ore grinding effect and the output.

3. Working Condition

According to a ball mill’s working principle, materials are mainly ground by its grinding media. Either too many or too less grinding media will affect the grinding effects so that a ball mill should be fed with a proper number of grinding media according to scientific and reasonable calculation.

In order to purchase a ball mill, you should get to know manufacturers from many aspects, including equipment, data on ore grinding tests, and actual production solutions. You’re advised to purchase equipment from standard big-scale manufacturers.

With several years’ experience in the production of ball mills, Hongxing tends to be mature and stable in techniques and processes. Hongxing Ball Mills are worthy of being purchased due to its excellent performance, low energy consumption, high output, and low price. You’re welcomed to consult us about more details.

If you’re looking for a professional ball mills manufacturer, we recommend you with Henan Hongxing Machinery, which excels in the production of the big-scale ball mill, small-scale ball mill, wet-type ball mill, dry-type one, etc. They are widely used in near one thousand enterprises in electric power, petrochemical industry, and metallurgy. Hongxing ball mills are popular in China and they are sold abroad.

For the sustainable development of resources exploitation and environmental protection, the new-type environmentally-friendly and energy-saving ball mill can meet the green mines production requirement, the brief introduction of which is as follows:

1. Energy Conservation

It adopts a special rolling shaft as the support structure of its tube. Compared with the traditional grinding mills’, the power of its electric motor can be decreased by 18-25%, 70% of lubricant can be saved, 90% of cooling water can be saved, and 20% energy can be saved comprehensively.

2. Environmental Protection

It is of a closed operation system, which can decrease dust pollution and the damage to operators. Besides, with the closed system, there will be less noise, which can realize the environmental mineral processing operation.

First of all, in recent years, the developmental trend of the mining industry in China is energy conservation and emission reduction. Therefore, in order to keep up with the age’s development step and to find out users’ requirements. In a word, the environmentally-friendly ball mills must be popular in the future market.Second of all, the environmentally-friendly and energy-saving ball mills are as good as the traditional ball mills in production capacity, grinding fineness, etc.

Besides, it focuses on energy-saving production and environmental protection so that it is bound to have a bright investment prospect as China calls for environmental mineral processing production.

Prev :This is the latest article!

Prev :This is the latest article!

Next : Ball Mill Type

Next : Ball Mill Type

Please tell us your needs like expected capacity, we have professional engineers to customize the proper production process for you.