Our industries are changing and advancing quickly,

and we know you need to be responsive to those changes.

Our industries are changing and advancing quickly,

and we know you need to be responsive to those changes.

04

Jun 2019

Aileen

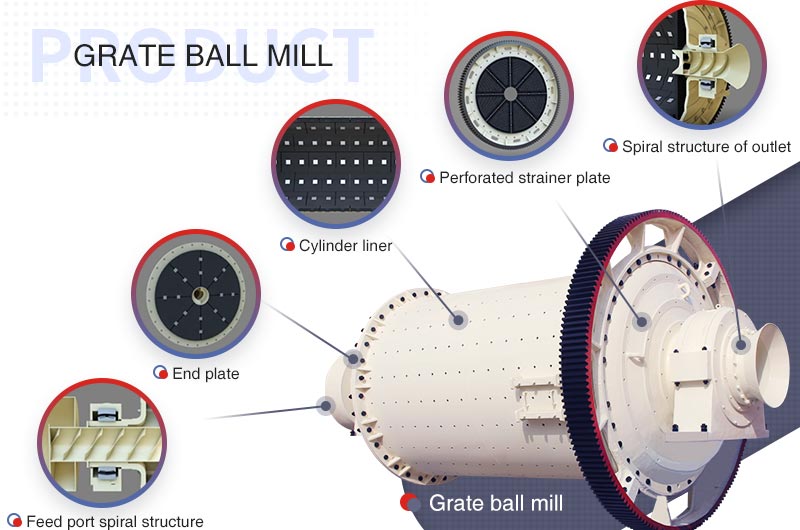

The lattice ball mill has a spiral structure inside the feed port, and the feed port is a common liner (end liner) without a bore. The cylinder body is an ordinary cylinder liner, and the discharge head is a lining plate with a boring hole (the rafter plate), and the inner spiral direction of the discharge port is consistent with the feed port.

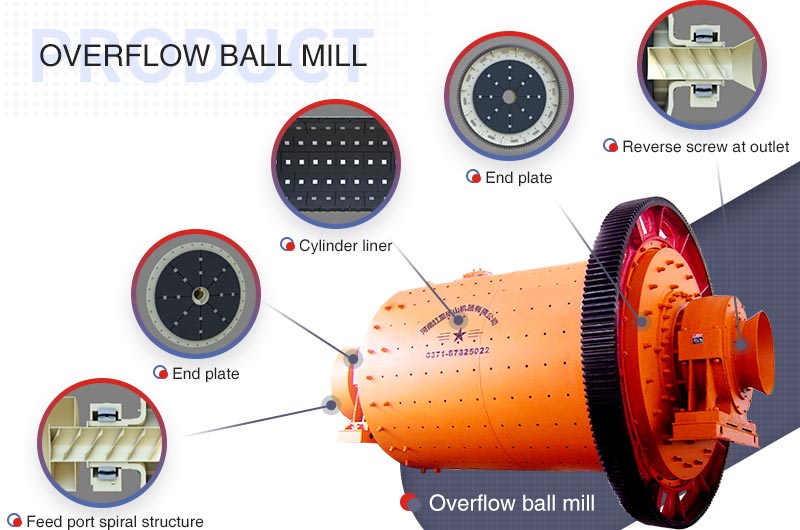

The structure of the feed end and the inside of the overflow ball mill is the same as that of the lattice type, but the discharge end is different. The overflow head of the overflow ball mill is the same as the normal end of the normal liner (end liner) without the boring. The direction of the spiral in the discharge port is opposite to the direction of the spiral in the feed port.

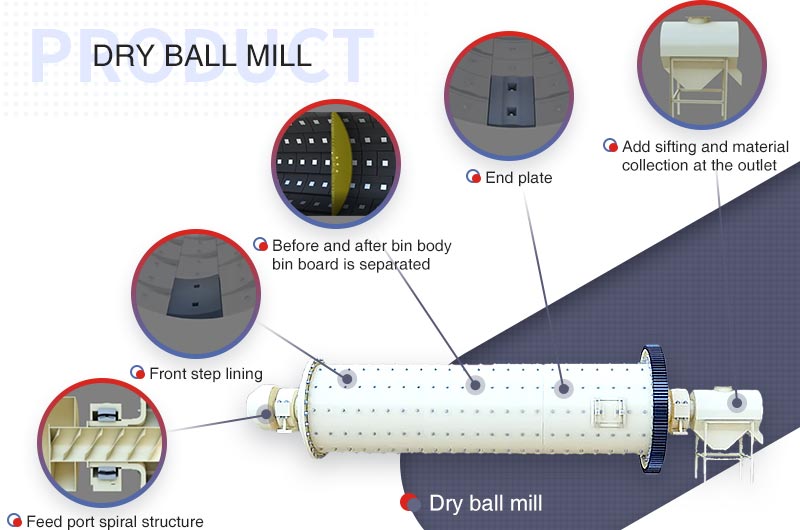

The principle of the feed end of the dry ball mill is the same as that of the lattice ball mill, but the cylinder is usually divided into two or three chambers. For example, the two warehouses are divided into a front warehouse and a rear warehouse. The front lining is a step lining with different thicknesses before and after; the rear ware is an ordinary lining. The front and rear bins are separated by a magazine. However, a sieve and discharge hood are added at the discharge port for sieving and collecting materials.

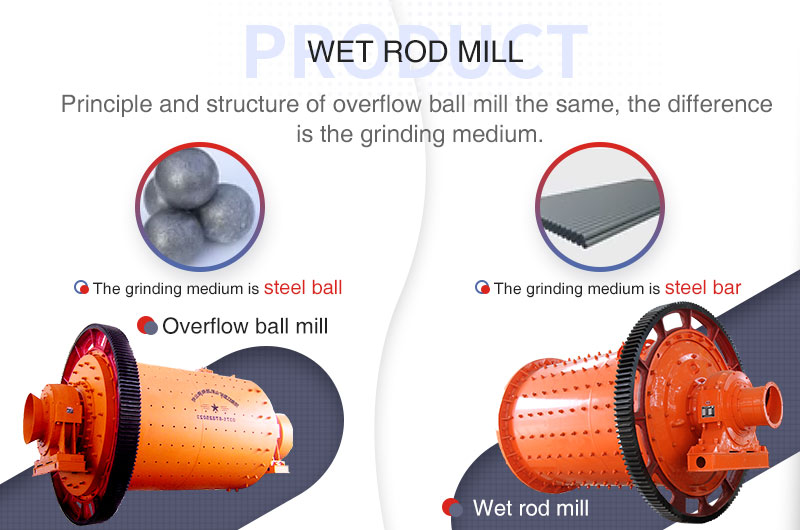

All the principles of the wet rod mill are the same as those of the overflow ball mill, except for the grinding medium inside. The grinding medium of the ball mill is a steel ball, and the grinding medium of the rod mill is a steel rod.

The wind sweeping coal mill is different from the other mills in the way of feeding and discharging. At the same time, the hot air enters to dry the material. Because the temperature is too high, the bearing needs water to be cooled, and the liner at the feeding end is the end liner (no Pupil), the two ends of the cylinder lining are inclined, and are spliced together and finally fixed on the cylinder by the bead. The outer side of the cylinder is covered with a layer of rock wool board (insulation material) fixed by galvanized steel plate On the cylinder, the discharge end, and the feed end also end liners (without boring). The spiral direction of the discharge port is opposite to the feed port, and finally, the material is extracted by the classifier.

Prev : How Much You Know About Ball Mills?

Prev : How Much You Know About Ball Mills?

Next : This is the last article!

Next : This is the last article!

Please tell us your needs like expected capacity, we have professional engineers to customize the proper production process for you.