Applied materials: barite, coal slime, potassium feldspar, tungsten carbide, copper ore, slag, hematite, white ash, gold ore, aluminum powder, etc.

The ball mill is the most important machine among the beneficiation equipment. Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and non-ferrous metal dressing, and glass ceramics.

Production capacity

0.65-615t/hFeeding size

≤25mm

Ball mill is the key equipment for grinding the material after being broken. Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and non-ferrous metal dressing, and glass ceramics. The ball mill is suitable for grinding various ores and other materials and is widely used in mineral processing, building materials, and chemical industries.

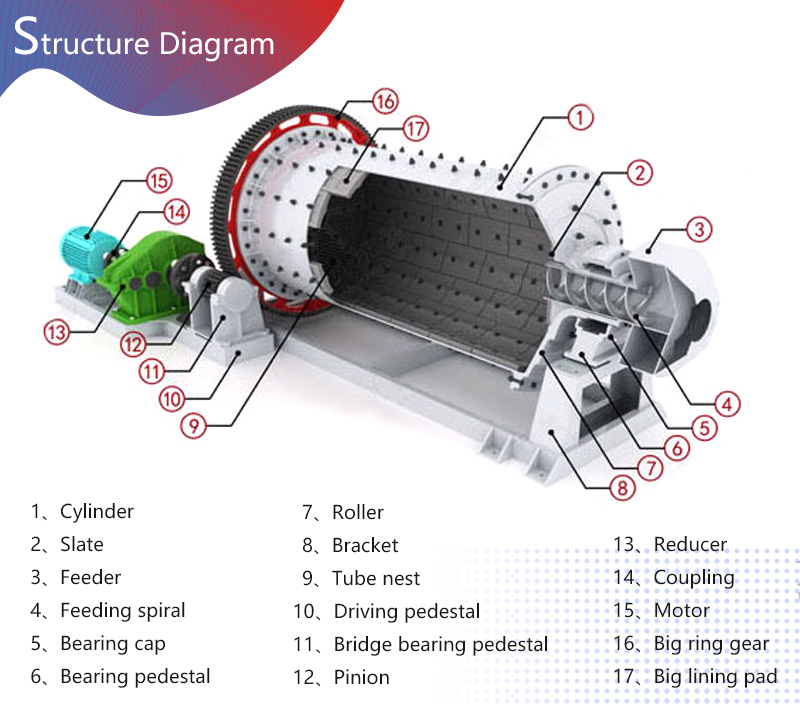

The material is fed into the mill by a drum feeder through a spiral cylinder with a hollow shaft. The grinding medium is installed in the barrel body. When the barrel body rotates, the grinding medium is attached to the wall liner surface of the barrel body due to the inertial centrifugal force. After being rotated together with the barrel body and brought to a certain height, the materials in the barrel body are broken by gravity.

In addition to the cyclic movement of ascending and falling, the grinding medium also causes sliding and rolling in the rotating cylinder body, causing grinding action between the grinding medium, the lining plate and the material to grind the material.

The ball mill is composed of the main part such as a feeding part, a discharging part, a turning part (a reduction gear, a small transmission gear, a motor, and electric control). The hollow shaft is made of cast steel, the inner lining can be replaced, the rotary large gear is processed by casting hobbing, the barrel is embedded with wear-resistant lining, which has good wear resistance. The machine runs smoothly, works reliably, which is energy-saving and environmentally friendly.

| Model | Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Total weight (t) |

| Ф900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | <25 | 0.074-0.4 | As per process conditions | 630 | 149 |

| Ф3600×4500 | 17 | 90 | <25 | 0.074-0.4 | As per process conditions | 850 | 169 |

| Ф3600×6000 | 17 | 110 | <25 | 0.074-0.4 | As per process conditions | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 |

| Model | Feeding capacity (t/time) |

Shell rotation speed (r/min) |

Reference motor (kw) |

Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

| Model |

Shell Specifications (mm)

|

Shell rotation speed (r/min) |

Feeding size (mm) |

Discharging size (mm) |

Processing capacity (t/h) |

Power (kw) |

Total weight (t) |

|

| Diameter | Length | |||||||

| MBS0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

| MBS0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| MBS1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| MBS1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| MBS1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| MBS2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| MBS2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| MBS2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| MBS2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| MBS2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| MBS3245 | 3200 | 4500 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |

Ball mill production line mainly consists of ball mill, hopper, feeder, conveyor, bucket elevator, powder classifier, dust collector and other associated equipment, we can make different design according to customers' requirements. When it works, materials are evenly fed into the ball mill by the feeder at the bottom of the raw material storage, after being ground , they outflow from the outlet and are transported to the powder classifier by the bucket elevator, after being classified, the coarse powder is sent back the mill by the screw conveyor, while the qualified powder is sent to the storage by the bucket elevator to be stored or packed. The powder dust is caught by the dust collector, and the powder is sent back to the mill to be reground, the clean air is released to the atmosphere by the blower.

How about the quality of the ball mill? How about the selected material?

How about the quality of the ball mill? How about the selected material?

In recent years, the requirements for environmental protection are getting higher and higher, I would like to ask how is the environmental protection effect of ceramic ball mills of your company?

In recent years, the requirements for environmental protection are getting higher and higher, I would like to ask how is the environmental protection effect of ceramic ball mills of your company?

Is the after-sales service of ceramic ball mill guaranteed?

Is the after-sales service of ceramic ball mill guaranteed?

After the purchase, will your company be responsible for the installation of the cement ball mill?

After the purchase, will your company be responsible for the installation of the cement ball mill?

What is the maximum grinding capacity of a ball mill?

What is the maximum grinding capacity of a ball mill?

What is the appropriate grinding concentration of the ball mill equipment?

What is the appropriate grinding concentration of the ball mill equipment?

In the ore dressing production, how many kinds of grinding methods are there for ball mill?

In the ore dressing production, how many kinds of grinding methods are there for ball mill?

Any more questions? We will be happy to help you!

For more detailed information about the product, If you have a specific inquiry, are looking for advice or simply want direct contact, we will be happy to assist you at all times. Leave a message/Email:info@hxjq.com

Mature technology

Mature technology

Extraordinary team

Extraordinary team

Shipping worldwide

Shipping worldwide

Professional service

Professional service

Please tell us your needs like expected capacity, we have professional engineers to customize the proper production process for you.